- Product techniques

- Skived fin heat sink

- Friction stir welded heat sink

- Heat pipe thermal module

- Water cooler

- Applications and industries

- Cooling solutions for electric car controllers

- Wind power converter cooling solution

- PV inverter cooling solution

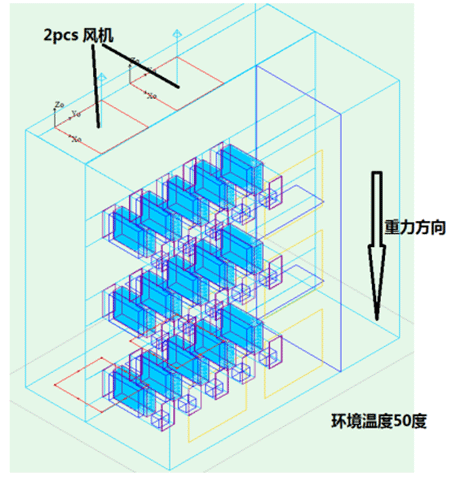

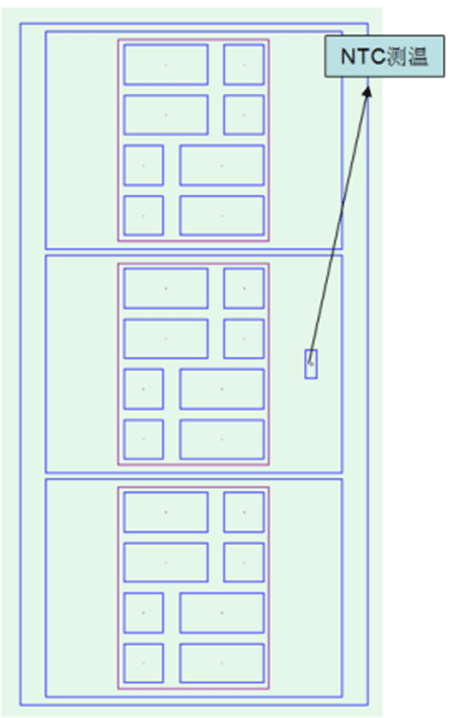

- Energy storage system cooling solution

-

Official account

Official website

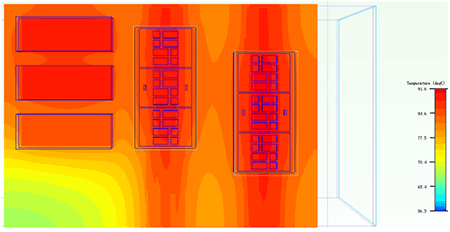

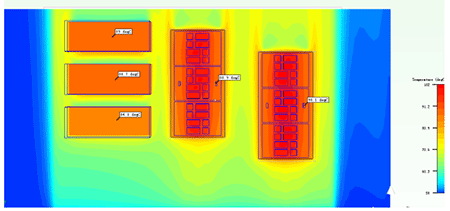

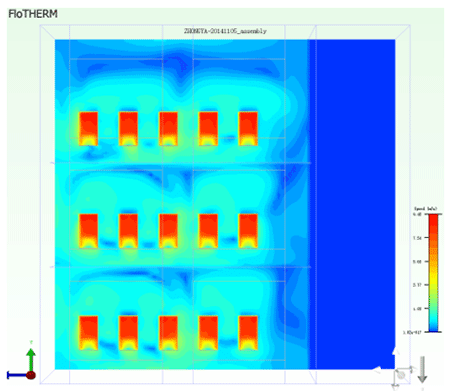

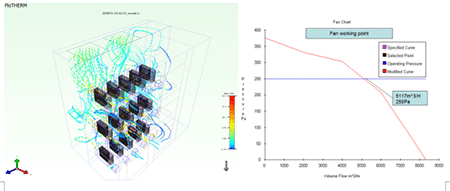

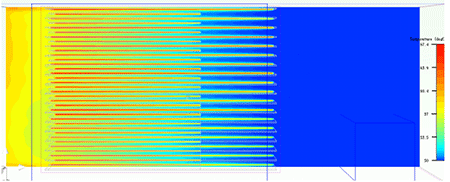

(Minimum air flow rate: 669.5m^3/H, pressure: 197.1Pa)

(Minimum air flow rate: 669.5m^3/H, pressure: 197.1Pa)