Cold forging is a technique for material forming at a temperature that is lower than the material's recrystallization temperature (typically means room temperature). Typically used cold forging materials include aluminum and its alloys, copper and its alloys which have a smaller resistance to deformation under room temperature and have higher plasticity. During the forming process, cold forging allows work hardening (strain hardening) so that both the strength and hardness are enhanced.

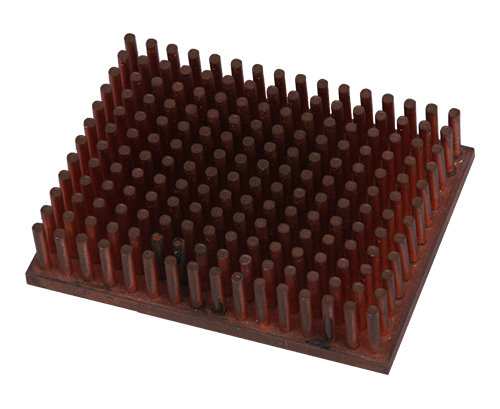

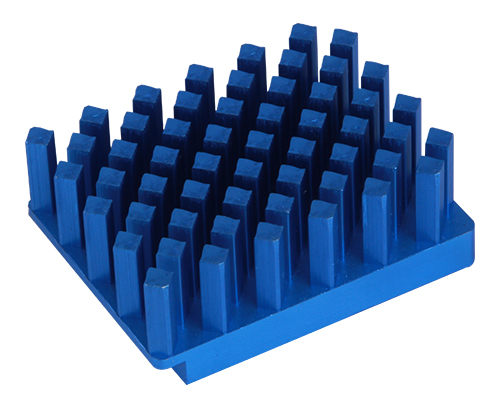

Cold forging technique has been widely used by heat sink manufacturers in the production of light source heat sinks and LED heat sinks. Winshare Thermal is one of the few companies who used cold forging to produce heat sinks in early days and we have accumulated abundant experience of cold forging techniques. In addition to the production of heat sinks for typical light sources, Winshare Thermal has gained experiences in the manufacturing techniques for high power cold forging heat sinks. We have resolved the problems such as the low thermal conductivity of die-casting micro-channels and higher costs for machining micro-channels. We have already applied our expertise to cooling solutions including high-voltage inverters, wind power converters, and electric motor controllers.

|

Metals

|

Minimum recrystallization temperature/℃

|

|

Copper (Cu)

|

200~270

|

|

Aluminum (Al)

|

100~150

|

We always carry out integrated design and manufacturing of our heat sinks by cold forging technique so as to ensure low thermal resistance and high thermal conducting effects. This can effectively guarantee the transfer of heat in a timely fashion so as to achieve the ultimate cooling effect. Moreover, cold-forging heat sinks have better mechanical performance, higher throughput and higher material utilization rate. Therefore, it is especially suitable for large batch productions in order to reduce the production costs.